Plastic bait molds are an essential tool for anyone interested in crafting their own soft plastic lures. These molds allow anglers to create custom lures that match specific fishing conditions, offering a more personalized approach to bait-making. Plastic bait molds come in a variety of shapes and sizes, and can be used to create everything from simple grubs to complex swimbaits. Whether you’re a seasoned pro or a beginner, learning how to use these molds opens up a whole new world of creativity in your fishing tackle box. With the growing popularity of custom baits, anglers now have the freedom to design lures tailored to specific water conditions, prey species, and desired action. This customization not only increases the effectiveness of fishing trips but also provides a rewarding hands-on approach to tackle creation.

History of Plastic Bait Molds

The evolution of plastic bait molds dates back to the early 20th century, when anglers first began experimenting with artificial lures to mimic the movement of live prey. Early fishing lures were made from wood, metal, and feathers, but it wasn’t until the 1950s and 1960s that soft plastic lures gained widespread popularity. The invention of plastisol—a type of liquid plastic that can be poured and molded—was a game-changer in the fishing industry. Innovators in the 1950s, such as the renowned fishing tackle creator, Paul Y. L. Tuttle, started developing plastic lures that mimicked the texture and flexibility of natural prey, revolutionizing the fishing world. These plastic lures could be poured into molds to create intricate shapes that were previously impossible with wooden or metal lures.

By the 1970s, the development of plastic bait molds had taken off, allowing hobbyists and small businesses to produce their own lures in bulk. With the rise of specialized plastic molds, anglers were able to experiment with custom designs and colors, creating lures that were highly effective in a variety of fishing environments. This led to the growth of the “soft plastics” market, which remains a cornerstone of modern fishing today. The introduction of silicone molds and the improvement of mold designs has further advanced the precision and durability of custom lures, making plastic bait molds an essential tool for anglers looking to gain a competitive edge.

The Benefits of Soft Plastic Lure Molds for Custom Fishing Baits Soft plastic lure molds offer several advantages for avid fishermen looking to enhance their bait selection. By using soft plastics, you can create lures with lifelike actions that can mimic the movements of prey in the water. Custom-made lures also allow you to experiment with different colors, textures, and sizes, giving you an edge over conventional, store-bought lures. Moreover, soft plastic lures tend to have a more durable and realistic feel in the water, which can lead to better strike rates.

Choosing the Right Plastic Lure Molds for Your Fishing Needs When selecting plastic lure molds, it’s important to consider the type of fishing you plan to do. Whether you’re targeting bass, trout, or pike, each species may require a different style of lure. Plastic bait molds can come in a wide array of designs, from worms to creature baits, each offering unique advantages in various fishing conditions. Take time to research the shapes, sizes, and materials that work best for your targeted catch to make sure your investment in molds will yield optimal results.

How to Use Soft Plastic Lure Molds to Create Your Own Fishing Baits Creating your own fishing lures from soft plastic materials can be a rewarding experience. Once you have selected your soft plastic lure molds, the process involves heating your material, pouring it into the mold, and letting it cool to take on its shape. You can use different additives to achieve the perfect consistency and softness, or even experiment with injecting color to give your lures a unique look. With practice, you can refine your technique and start producing lures that outperform those bought from the store.

Top Materials to Use for Plastic Bait Molds and Lures The success of your soft plastic lures depends largely on the quality of the materials you use. Plastisol, a common material for creating soft plastic baits, is widely regarded for its flexibility and durability. Other materials, such as silicone and rubber, can also be used depending on the specific requirements of your mold. Understanding the properties of each material will help you choose the right one for your mold, ensuring your lures will be effective, long-lasting, and realistic in appearance.

The Art of Customizing Plastic Bait Molds: Adding Color, Scent, and Texture Customization is key when it comes to creating successful soft plastic lures. Beyond simply choosing a mold, you can enhance your lures by adding various colors, scents, and textures to make them even more enticing to fish. By injecting different colored plastics or adding glitters and flakes, you can mimic the colors and sheen of local prey species. Furthermore, incorporating scents into the mix can help attract fish to your bait. Experimenting with different textures, such as ridges or fins, can also make your lure appear more natural and appealing.

Maintaining and Storing Plastic Lure Molds for Longevity Taking care of your plastic bait molds is essential for ensuring they last over time and continue to produce quality lures. Proper cleaning after each use is crucial to prevent the buildup of residual plastic that could affect future casts. It’s also important to store your molds in a cool, dry place to prevent warping or degradation of the material. Regular maintenance, such as lubricating the mold surfaces with a mold release agent, will help your molds stay in excellent working condition for many years of use.

Exploring Different Types of Plastic Bait Molds for Versatile Fishing Baits

Plastic bait molds come in a variety of designs that allow anglers to craft baits for different fishing situations. From traditional worm molds to more intricate crawfish or shrimp shapes, there’s a mold for virtually every fishing need. For anglers who prefer to target specific species or match local forage, using a mold that mimics a fish’s natural prey can significantly increase success rates. By diversifying your selection of molds, you can ensure that you have a custom bait for any fishing adventure.

How to Improve the Durability of Your Soft Plastic Lures Using Custom Molds

Durability is one of the key factors in creating effective soft plastic lures. Molds can be used to craft baits that are both strong and flexible, helping them withstand multiple strikes from fish without breaking apart. One of the most important aspects of this is the type of plastic material you use, as well as any additives that can improve the toughness of the lure. Understanding how to adjust the thickness and flexibility of your lures can help extend their lifespan, making them a more cost-effective option for long-term use.

The Science Behind Soft Plastic Lure Molds: Understanding the Pouring Process

The process of making soft plastic lures with molds is more than just pouring plastic into a cavity. Understanding the science behind this process—such as temperature control, the proper mix of plastisol, and the speed at which the material is injected—can make a significant difference in the quality of the finished product. Even slight changes in temperature or technique can affect the final texture, firmness, and durability of the lure, so mastering the pouring process is key to producing high-quality, effective baits.

How to Scale Up Production with Plastic Bait Molds for Commercial Use

For those interested in turning their hobby of making soft plastic lures into a business, scaling up production is an important consideration. This involves not only acquiring a larger quantity of molds but also understanding how to streamline the manufacturing process. Investing in high-quality, durable plastic bait molds and setting up an efficient workflow can help produce a large volume of lures without sacrificing quality. With the right equipment and techniques, you can create a steady supply of custom baits for commercial distribution or personal use.

Innovative Techniques for Enhancing the Action of Your Soft Plastic Lures Using Molds

One of the key reasons custom soft plastic lures are so popular is the ability to fine-tune their action in the water. By experimenting with different mold designs, you can create baits that have a specific, lifelike motion. Adding features such as tails that wiggle or bodies that float or sink at certain rates can make a significant difference in the lure’s effectiveness. Understanding hydrodynamics and how different shapes and textures affect a lure’s action can help you craft baits that attract fish more effectively.

Safety Tips and Best Practices for Working with Plastic Lure Molds

When working with plastic bait molds, safety should always be a top priority. Plastisol and other materials used in making soft plastic lures often require high temperatures to melt, which can be hazardous if not handled properly. It’s important to wear protective gloves, eye protection, and work in a well-ventilated area. Additionally, understanding the correct temperature range for different plastics and how to avoid overheating can prevent accidents and ensure the materials perform as expected. Following proper safety guidelines will keep the crafting process enjoyable and safe.

Troubleshooting Common Issues with Plastic Lure Molds and How to Fix Them

While making custom soft plastic lures can be a rewarding process, it’s not uncommon to encounter issues along the way. Common problems such as air bubbles, warped molds, or lures that don’t properly take shape can be frustrating. Learning how to troubleshoot and address these issues is an essential skill. Whether it’s adjusting the pouring technique, improving the mold’s release properties, or ensuring the right consistency of your material, knowing how to fix problems will improve your results and give you more confidence in the molding process.

Maximizing Efficiency in Soft Plastic Lure Production with Multiple Molds

Using multiple plastic bait molds at once can significantly increase the efficiency of your lure-making process. By creating several baits at the same time, you can minimize the time spent on each individual mold and quickly build up a collection of custom lures. This technique is especially useful if you’re producing baits for commercial purposes or preparing for a season of fishing. Learning how to manage several molds, maintain consistent quality, and streamline your workspace can help you create a high volume of baits in less time.

How to Add Realistic Features to Soft Plastic Lures Using Specialized Molds

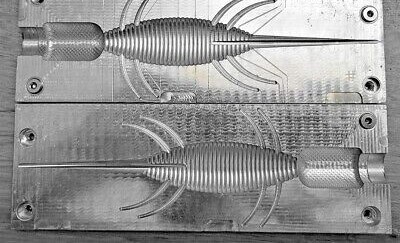

For many anglers, the realism of a bait can make the difference between attracting fish and getting ignored. Specialized plastic bait molds allow for the creation of highly detailed features like fins, scales, or even veins on soft plastics, adding a lifelike quality to the lure. By using molds with these detailed designs, you can replicate the exact appearance of local prey, making your lures even more enticing to fish. Additionally, adding features like scent chambers or rattles can further enhance the bait’s realism and effectiveness.

Exploring Eco-Friendly Alternatives in Plastic Lure Molds

As the fishing industry continues to grow, the environmental impact of plastic baits has become an important consideration. Eco-friendly alternatives to traditional plastics are becoming more available for use in soft plastic lure molds. These materials often feature biodegradable properties or are made from recycled plastics, offering an environmentally conscious option for anglers who want to reduce their carbon footprint. By exploring these alternatives, you can still create high-quality, effective baits while also contributing to more sustainable fishing practices.

Advanced Techniques for Customizing Plastic Lures with Dual-Color Molds

One of the most popular ways to increase the appeal of soft plastic lures is by using dual-color molds, which allow anglers to create baits with multiple color layers. This technique mimics the natural color patterns found in prey species, adding extra visual attraction to the lure. By mastering the process of injecting different colored plastics into specific sections of the mold, you can create lures with complex, vibrant patterns that are more likely to attract fish. Dual-color molds offer an exciting way to experiment with color combinations to find the most effective designs for various fishing conditions.

The Impact of Temperature Control on Soft Plastic Lure Mold Performance

Temperature plays a critical role in the success of soft plastic lure molding. Both the mold and the plastic material must be heated to precise temperatures to ensure the best results. If the plastic is too hot, it may degrade or cause the mold to warp, while temperatures that are too low can lead to incomplete or misshapen lures. Mastering temperature control—whether using a heat gun, stove, or microwave—ensures that the plastic cures properly and takes on the desired consistency, leading to better-quality lures and fewer mistakes during the molding process.

How to Use Silicone Molds for Creating Unique Soft Plastic Lures

Silicone molds have become a popular choice for creating soft plastic lures due to their flexibility and ability to capture intricate details. Silicone offers several advantages, including the ability to handle high temperatures and ease of mold release, making it perfect for repetitive use. Additionally, silicone molds allow for the production of baits with unique shapes and textures that may be difficult to achieve with traditional metal molds. By experimenting with different silicone mold designs, you can create one-of-a-kind lures tailored to your specific fishing needs.

Optimizing Soft Plastic Lure Mold Designs for Better Hooksets and Durability

When designing soft plastic lures using molds, it’s crucial to consider how the shape and structure of the bait will affect hooksets and overall durability. Certain mold designs can be optimized to ensure the lure remains intact during multiple strikes without tearing or deforming. Features like reinforced bodies, thicker sections, or more flexible tails can enhance both the strength and effectiveness of the lure in catching fish. By strategically altering mold designs to incorporate these durability-enhancing features, you can create lures that withstand aggressive strikes and last longer in the water.

Creating Multi-Species Soft Plastic Lures with Universal Mold Shapes

Anglers often seek versatile soft plastic lures that can be used for a variety of fish species. By using universal mold shapes, you can design baits that are effective across different types of fishing, whether you’re targeting bass, walleye, or pike. These molds typically feature classic lure profiles that mimic a broad range of prey. By customizing these base shapes with color variations, added textures, or scent additives, you can create multi-species lures that are adaptable for different fishing environments and increase your chances of success, no matter the species you’re targeting.

Conclusion

Plastic bait molds offer anglers a powerful tool for creating custom soft plastic lures tailored to specific fishing needs. Whether you’re crafting simple worms, detailed creature baits, or multi-colored swimbaits, the ability to design and manufacture your own lures can significantly enhance your fishing experience. The advantages of using plastic bait molds go beyond just cost savings; they allow for the creation of lures with precise actions, lifelike features, and personalized attributes that can outperform store-bought options.

From choosing the right mold material and experimenting with color and texture to mastering temperature control and troubleshooting common issues, the process of creating your own lures involves both creativity and technical know-how. With advancements in mold designs, such as dual-color and silicone molds, as well as eco-friendly alternatives, the world of plastic lure crafting continues to evolve.

By understanding the nuances of soft plastic lure mold making, you can maximize both the effectiveness and durability of your baits. Whether you’re an experienced angler looking to expand your tackle box or a beginner keen on experimenting with new techniques, using plastic bait molds offers endless opportunities for innovation and success in fishing.

Recent Comments