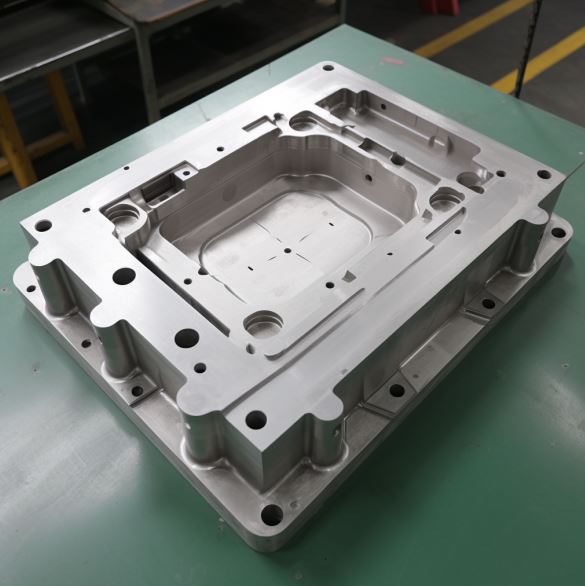

Aluminium Die Casting and Aluminium Die Casting China

Aluminium die casting is nostly usded in large manufacturing units. This process is very much acclaimed for tis reliabeility and stregth. Usded in verious industries. They are cost-effective and immensely cater to the demand of users. Their advent cn be seen more in the aerospace industry where precision and quality is vital. Components maded

from cast aluminum are substantial and are resistant to harsh weather condition. Product crafted from aluminum is mostly used in aviation and commercial industries. Of immense potentially, these casted aluminum products gel with other Metals and offer flexibility by all means. Aluminium die casting metal parts are comparatively better than plastic injection molded parts, tag for quality, it bags excellence in all manufacturing endeavor. These aluminum die casting parts are a natural shield doe RF and EMI and prevent radio frequency. Stronger and stiffer cast aluminum pars are more stable dimensionally tolerance and most exquisite finish. Ensuring more uniformity and dimension accuracy, aluminum cast parts have drawn that attention of the users. Its applicability in aircraft industry mark safety by all means. Light in weight and durable at high temperature these die cast. Products are of enormous benefit to aviation industry which includes aircraft seats. Components for the passenger cabin or baggage compartment etc.

Die casting technology is marked for its high quality and functional parts. Used in making electronic devices like cell phones and MP3 players. Digital cameras and flat-screen monitors and many others they also form an essential part of the construction industry. What aluminum die casting is known for producing precision parts in high volume at low costs. While ensuring the excellent surface finish, they eliminate the need for post machining. Manufacturing under the strict supervision of experts. Die cast aluminum parts assuring impeccability and comply with the international standard. Owing to superior attributes, there casted parts are commonly used in electrical. Telecom, automobile and plastic industries. When it comes to strength and weight zinc, aluminum and magnesium die casting parts offer the best pact.

There may be different operations that may enlist the services of a provider. Before you do so, it is advisable to spend some time, to choose a reputable and dependable service firm. Quality aluminum die casting can tale your operational process to a higher level and ultimately and profit margins. With the advancement of technology, automotive has emerged as the favored method of casting as it gives a well finished element in perfect performance. These processed are utilized everywhere from the manufacturing to the auto industry. Ultimately, the objective should be to employ services provider that can provide the lowest prices and quality standards. Therefore, choosing a company that accommodates several industries has always been useful step.

Here are a few tips that you should keep in mind before availing the services, Check if the company is equipped with the lasted machines for offering the best results. Also, it should have the appropriate infrastructure to provide you with cost0effective solutions. Make a note to keep these tips in mind and you would never wrong in choosing the best dealer for great deals, weather you are in the automotive of electronics sector.

Finally die casting parts made in aluminum, zinc or magnesium will be the best market in the future

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.