Arizona has established itself as a significant hub for manufacturing industries, with injection molding playing a pivotal role in its economic growth. Injection molding is a highly versatile and efficient manufacturing process used to produce complex plastic parts for various industries, including automotive, medical, aerospace, consumer goods, and electronics. The state’s strategic location, coupled with its business-friendly environment and skilled workforce, makes Arizona an attractive destination for companies specializing in injection molding. Over the years, several injection molding companies in Arizona have built a reputation for delivering high-quality plastic components tailored to meet diverse client needs.

History of Injection Molding in Arizona

The history of injection molding in Arizona is closely tied to the state’s industrial development in the mid-20th century. As industries such as aerospace and defense began to thrive in Arizona, the demand for durable and lightweight plastic components surged. This led to the establishment of the first injection molding companies in the region. Early adopters of injection molding technology in Arizona primarily catered to the needs of the military and aerospace sectors during the post-World War II industrial boom.

By the 1970s and 1980s, injection molding companies in Arizona began expanding their capabilities to serve a broader range of industries, such as medical equipment manufacturing and consumer products. Advances in technology during this period allowed companies to enhance precision and efficiency, making injection molding a more attractive option for mass production. Arizona’s commitment to innovation and its support for small and medium-sized enterprises further fueled the growth of this sector.

Today, Arizona is home to numerous injection molding companies that combine cutting-edge technology with sustainable practices to deliver exceptional results. From prototyping to large-scale production, these companies continue to play a crucial role in supporting the state’s economy and driving innovation across various industries.

Why Arizona is a Strategic Location for Injection Molding

Business-Friendly Policies and Infrastructure

Arizona offers a favorable business climate with low taxes, reduced regulatory burdens, and incentives for manufacturers. The state has developed infrastructure that supports manufacturing growth, including industrial parks, transportation networks, and reliable energy sources. Injection molding companies benefit from Arizona’s proximity to major markets like California, Texas, and Mexico, allowing them to streamline logistics and reduce shipping costs.

Access to Skilled Labor and Workforce Training

Arizona has a growing pool of skilled workers trained in plastic manufacturing, mold design, and automation. Many companies collaborate with local technical schools and universities to ensure a steady supply of trained professionals in injection molding technology. These institutions offer specialized training in areas such as mold fabrication, quality control, and machine operation.

Support for Innovation and Advanced Manufacturing

Injection molding companies in Arizona invest heavily in research and development to enhance their manufacturing processes. The state’s support for innovation, including funding opportunities and partnerships with engineering institutions, allows manufacturers to adopt cutting-edge technologies such as automation, robotics, and precision molding techniques.

Industries Served by Injection Molding Companies in Arizona

Automotive Industry

The automotive sector relies on injection molding companies in Arizona for high-performance plastic components, including interior panels, lighting fixtures, bumpers, and under-the-hood parts. These companies specialize in producing lightweight, durable parts that enhance fuel efficiency and vehicle performance.

Aerospace and Defense

Arizona is home to several aerospace and defense manufacturers that require precision-molded plastic components. Injection molding companies in the state produce parts for aircraft interiors, control panels, and structural components. The aerospace industry demands high-quality materials with excellent heat resistance, strength, and lightweight properties, which injection molding companies in Arizona deliver through advanced engineering plastics.

Medical and Healthcare Industry

Medical injection molding companies in Arizona manufacture precision plastic parts for surgical instruments, diagnostic equipment, and medical devices. These components must meet strict regulatory standards for biocompatibility, sterilization, and durability. Many companies in Arizona have ISO 13485 certification, ensuring compliance with medical industry regulations.

Electronics and Consumer Goods

Electronics manufacturers in Arizona depend on injection molding for producing enclosures, connectors, and insulating components. Consumer goods companies utilize injection molding for creating durable plastic products, including household items, packaging, and sporting goods.

Key Injection Molding Processes Used in Arizona

Custom Injection Molding

Many injection molding companies in Arizona specialize in custom plastic parts, offering tailored solutions for clients in different industries. Custom molding involves designing and fabricating unique molds to produce complex and high-performance plastic components.

Overmolding and Insert Molding

Overmolding is a technique where one material is molded over another to create a single, integrated part. This process enhances grip, aesthetics, and functionality in products such as tools, medical devices, and electronic housings. Insert molding, on the other hand, involves embedding metal or other materials within the plastic part, often used for electrical connectors and structural reinforcements.

High-Precision and Tight-Tolerance Molding

Injection molding companies in Arizona use advanced molding techniques to achieve tight tolerances and high precision in plastic parts. This is especially important in industries such as medical devices and aerospace, where component accuracy is critical.

Micro Molding

Some Arizona injection molding companies specialize in micro molding, a process used to manufacture extremely small plastic parts with intricate details. Micro-molded components are commonly used in medical devices, electronics, and telecommunications.

Sustainability in Arizona’s Injection Molding Industry

Eco-Friendly Materials and Recycling

Many injection molding companies in Arizona focus on sustainability by using biodegradable and recyclable plastics. Companies are adopting closed-loop manufacturing systems where excess plastic material is reprocessed and reused, reducing waste and environmental impact.

Energy-Efficient Manufacturing

Manufacturers in Arizona are investing in energy-efficient machinery and smart manufacturing technologies to reduce power consumption. Electric and hybrid injection molding machines are replacing traditional hydraulic presses, leading to lower operational costs and reduced carbon footprints.

Challenges Faced by Injection Molding Companies in Arizona

Supply Chain Disruptions

Global supply chain challenges have affected the availability of raw materials for injection molding. Companies in Arizona are mitigating these issues by diversifying suppliers, investing in local sourcing, and maintaining inventory buffers to ensure continuous production.

Rising Costs of Materials and Labor

The cost of plastic resins, additives, and skilled labor has been increasing, impacting production costs. Injection molding companies in Arizona are adopting automation and lean manufacturing practices to maintain efficiency and cost-effectiveness.

Regulatory Compliance

Manufacturers in the medical, automotive, and aerospace industries must comply with strict regulations and quality standards. Companies in Arizona ensure compliance by implementing rigorous quality control systems, obtaining industry certifications, and following best practices in process validation and testing.

Plastic Mold Manufacturing and Tooling in Arizona

Mold design and tooling are essential components of the injection molding industry in Arizona. Many companies offer in-house mold manufacturing services to create high-quality plastic mold that ensure precision and consistency in production. Advanced mold-making techniques include:

- CNC machining for high-precision tooling

- EDM (Electrical Discharge Machining) for intricate mold details

- Multi-cavity molds for high-volume production

- Rapid tooling for quick prototyping and small-batch manufacturing

These capabilities allow Arizona-based companies to deliver cost-effective and high-performance plastic parts for various industries.

Expansion of Injection Molding Companies in Arizona

Arizona’s injection molding industry is growing rapidly due to increasing demand for precision plastic components in various sectors. Companies are expanding their production capabilities, investing in new technologies, and adopting sustainable practices to stay competitive. As the industry continues to evolve, Arizona remains a prime location for injection molding due to its skilled workforce, advanced manufacturing infrastructure, and access to key markets.

Advanced Injection Molding Technologies in Arizona

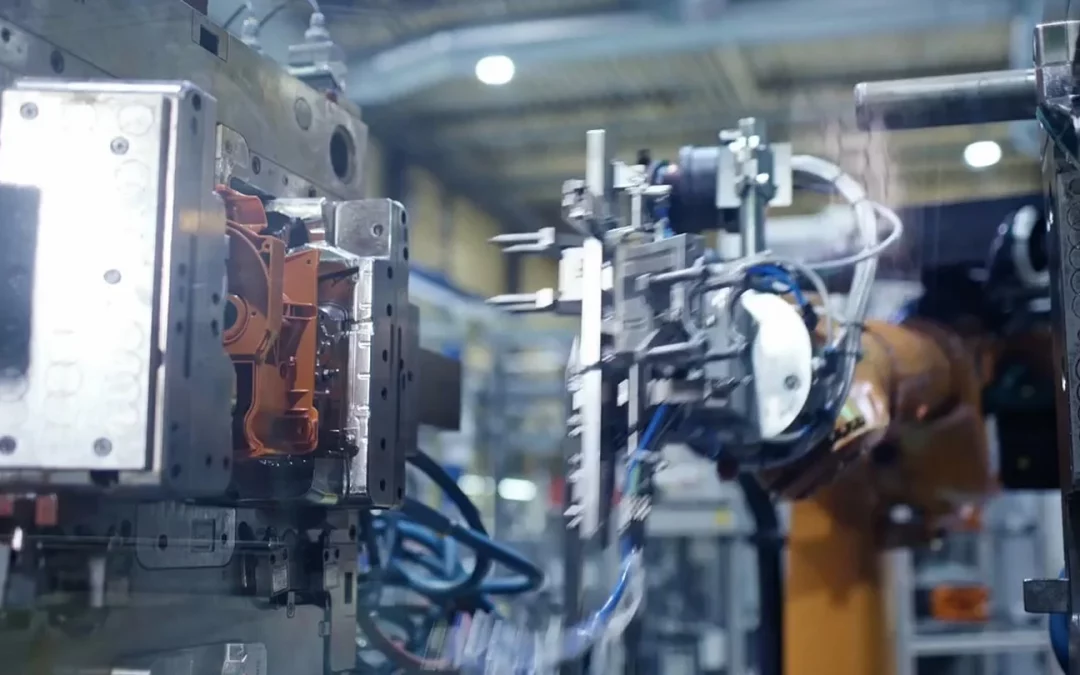

Automation and Robotics in Injection Molding

Injection molding companies in Arizona are increasingly incorporating automation into their production lines. Robotics and automated systems help streamline the molding process, reduce cycle times, and improve product consistency. Automated solutions also allow manufacturers to reduce labor costs and minimize human errors, resulting in higher efficiency and precision in plastic part production.

Injection Mold Design and Engineering Innovations

Arizona-based companies are investing in advanced mold design and engineering solutions to improve the efficiency and quality of molded parts. The use of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software has revolutionized mold-making, allowing for faster design iterations and enhanced precision. Innovations such as conformal cooling, where cooling channels are optimized to improve heat dissipation, have significantly reduced cycle times and improved part quality.

Multi-Shot and Overmolding Capabilities

Many injection molding companies in Arizona have adopted multi-shot molding and overmolding techniques to produce complex, multi-material components. Multi-shot molding allows manufacturers to inject different materials into a single mold, creating parts with enhanced functionality and aesthetic appeal. Overmolding, on the other hand, involves molding one material over another to improve grip, durability, and product performance.

Custom Injection Molding Solutions in Arizona

Low-Volume vs. High-Volume Production

Injection molding companies in Arizona cater to both low-volume and high-volume production needs. Low-volume molding is ideal for prototyping, specialized applications, and short production runs, while high-volume molding is used for mass production. Companies that offer flexible production capabilities can serve a wider range of clients, from startups to large-scale manufacturers.

Prototype and Rapid Injection Molding

Many Arizona-based manufacturers specialize in rapid injection molding, allowing businesses to develop and test prototypes before moving to full-scale production. Rapid molding services use advanced mold fabrication techniques to reduce lead times and accelerate product development. Companies can create prototype molds that simulate final production conditions, ensuring that design flaws are identified and corrected early in the process.

Custom Material Selection for Industry-Specific Applications

Injection molding companies in Arizona work with a wide range of plastic resins to meet industry-specific requirements. Commonly used materials include:

- ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and impact resistance, ABS is widely used in automotive, consumer electronics, and industrial applications.

- Polycarbonate (PC): A high-strength, heat-resistant plastic commonly found in aerospace, medical, and safety equipment.

- Polyethylene (PE) and Polypropylene (PP): These materials are used for packaging, household items, and medical applications due to their chemical resistance and durability.

- Nylon (PA): Frequently used in automotive, electrical, and industrial applications for its excellent mechanical properties and wear resistance.

By offering custom material selection, Arizona’s injection molding companies ensure that clients receive high-quality plastic parts tailored to their specific needs.

Sustainability Initiatives in Arizona’s Injection Molding Industry

Biodegradable and Recyclable Plastics

Many injection molding companies in Arizona are shifting toward eco-friendly materials. The adoption of biodegradable plastics and recyclable resins helps reduce plastic waste and promotes environmental sustainability. These materials are being increasingly used in packaging, medical applications, and consumer goods.

Waste Reduction and Lean Manufacturing

Arizona manufacturers are implementing lean manufacturing principles to optimize resource utilization and minimize waste. By reducing scrap rates, improving process efficiency, and recycling excess materials, companies can lower production costs while promoting sustainability.

Energy-Efficient Molding Machines

Energy-efficient injection molding machines, such as all-electric and hybrid systems, are replacing traditional hydraulic machines in many Arizona facilities. These machines consume less power, reduce maintenance costs, and offer greater precision and repeatability in the molding process.

Supply Chain and Logistics Advantages in Arizona

Strategic Location for Distribution

Arizona’s geographical location offers significant advantages for injection molding companies. The state is well-connected to major markets such as California, Texas, and Mexico, providing easy access to distribution networks. This allows manufacturers to reduce shipping costs and lead times, making it easier for businesses to meet customer demands.

Local Sourcing and Supply Chain Resilience

To mitigate supply chain disruptions, many Arizona injection molding companies are prioritizing local sourcing for raw materials and mold fabrication. By working with local suppliers, manufacturers can reduce dependency on international supply chains and ensure a more stable production process.

Future Trends in Arizona’s Injection Molding Industry

Smart Manufacturing and Industry 4.0

The integration of Industry 4.0 technologies is transforming injection molding in Arizona. Smart manufacturing solutions, including IoT (Internet of Things)-connected machines, AI-driven analytics, and predictive maintenance, are enhancing efficiency and reducing production downtime. These innovations enable manufacturers to monitor real-time data, optimize workflows, and improve overall quality control.

Growth of On-Demand and Just-in-Time Manufacturing

As businesses seek to reduce inventory costs and respond quickly to market changes, on-demand and just-in-time (JIT) manufacturing models are becoming more popular. Injection molding companies in Arizona are offering flexible production schedules to accommodate smaller, customized orders without compromising quality or efficiency.

Expanding Use of High-Performance Polymers

With industries such as aerospace, medical, and electronics demanding more durable and heat-resistant materials, injection molding companies in Arizona are focusing on high-performance polymers. These advanced plastics provide superior strength, chemical resistance, and temperature stability, making them ideal for challenging applications.

Collaboration with International Partners

Injection Mold China Partnerships

Arizona’s injection molding companies often collaborate with international partners, including mold manufacturers in China, to enhance their production capabilities. Many businesses source molds from Injection mold China suppliers due to cost-effectiveness, high precision, and advanced mold fabrication expertise. By combining local manufacturing with global mold sourcing, companies in Arizona can offer competitive pricing and high-quality products to their customers.

Conclusion

Injection molding companies in Arizona continue to thrive due to their commitment to innovation, efficiency, and sustainability. With advancements in automation, smart manufacturing, and eco-friendly materials, these companies are well-equipped to meet the evolving demands of industries such as automotive, aerospace, medical, and consumer goods. By leveraging Arizona’s strategic location, skilled workforce, and strong supply chain network, injection molding companies can provide high-quality plastic components while maintaining competitive costs. As the industry continues to expand, businesses in Arizona will play a crucial role in shaping the future of injection molding through technological advancements, sustainable practices, and global collaborations.

Recent Comments