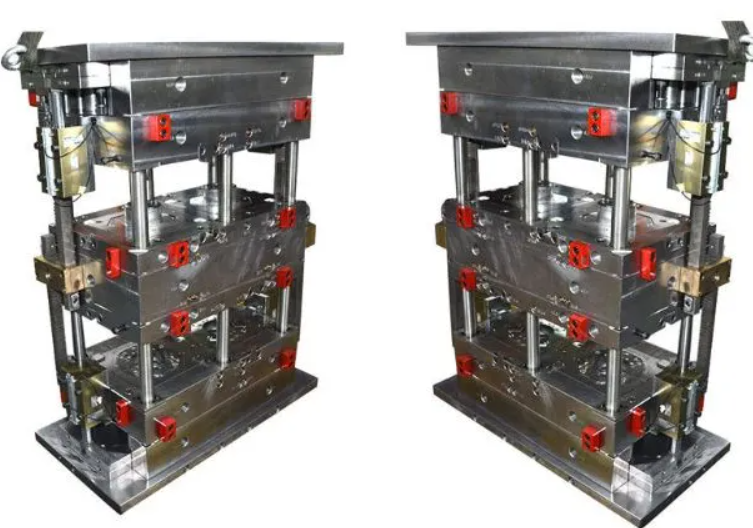

A stack mold, also known as a stack mold system or stack molding or multi-layer molding, is a specialized type of injection molding system that allows for the production of multiple plastic parts in a single molding cycle. It achieves this by using multiple mold cavities arranged in a vertical or stacked configuration within a single mold assembly. Stack molds are particularly useful for high-volume production and can significantly increase the output of a single molding machine, making them cost-effective for applications where efficiency and productivity are critical.

SINCERE TECH (plasticmold.net) is a plastic mold company that provides plastic injection mold solutions to industries of all types and sizes. Our state-of-the-art mold building facilities include high-speed CNC Machines and EDM Machining to create many types of high precision plastic injection molds, including complex speciality injection molds, such as two-shot molds, unscrewing molds, stack molds, insert mold, gas assist molds and many other types.

The Pros of Stack Molding

Here are some key features and advantages of stack moulds:

- Multiple Cavities: A stack mould consists of two or more sets of mold cavities stacked on top of each other. Each set of cavities functions as a separate mold. This design allows for multiple parts to be molded simultaneously in a single shot.

- Improved Productivity: Stack molds can produce twice as many parts as a traditional single-cavity mold in a single molding cycle, significantly increasing production output and reducing cycle times. The number of cavities in a stack mold can vary depending on the design and application.

- Space Efficiency: Stack molds save space compared to using multiple single-cavity molds, as they utilize a single molding machine and take up less floor space.

- Reduced Energy Consumption: While they produce more parts per cycle, stack molds generally use less energy per part, making them more energy-efficient in high-volume production scenarios.

- Cost Savings: Despite the initial investment in a stack mold system, it can lead to cost savings over time due to increased production efficiency, reduced labor costs, and lower energy consumption per part.

- Part Consistency: Stack molds offer excellent part-to-part consistency because all parts in a single cycle are produced under identical molding conditions.

- Complex Geometries: Stack molds can produce parts with complex and intricate geometries by utilizing multiple mold cavities for each part, allowing for the creation of undercuts, inserts, or multi-material components.

- Multiple Materials: Stack molds can be designed to accommodate multiple plastic materials, enabling the production of multi-material or multi-color parts in one molding cycle.

- Core and Cavity Variations: Stack molds can be designed with variations in core and cavity configurations, allowing for different part designs or sizes within the same mold assembly.

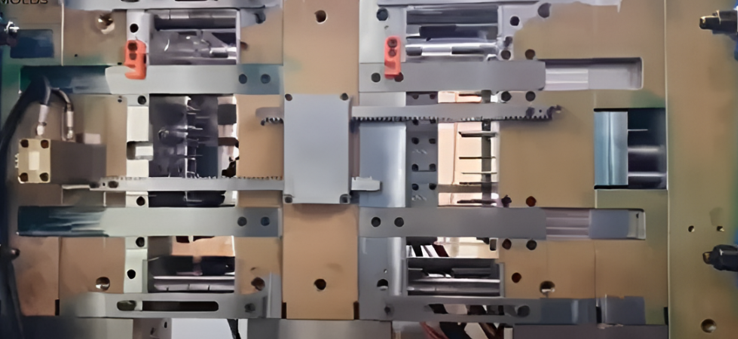

- Cooling System: Efficient cooling systems are essential in stack molds to maintain consistent part quality and ensure that all parts solidify properly.

Stack molds are commonly used in industries that require high-volume production of parts, such as the automotive, packaging, consumer goods, and medical device industries. The design and construction of a stack mold require careful engineering and consideration of factors like cooling, ejection, and maintenance to ensure their reliable and efficient operation.

The Cons of Stack Molding

While stack molds offer numerous advantages for high-volume plastic injection molding, they also come with some disadvantages and challenges. Here are some of the drawbacks and considerations associated with stack molds:

- High Initial Cost: Stack moulds are more complex and costly to design, manufacture, and maintain than single-cavity molds. The upfront investment can be a significant barrier for some manufacturers.

- Complex Design and Engineering: The design and engineering of stack injection molds are more intricate and demanding than those of single-cavity molds. They require careful consideration of factors such as cooling, ejection, and alignment to ensure proper functioning.

- Increased Maintenance: Stack molds have more components, including moving parts and cooling systems, which can require more maintenance and upkeep than traditional molds. Proper maintenance is crucial to prevent downtime and ensure consistent production.

- Longer Setup Times: Setting up and fine-tuning a stack injection mold can take more time than setting up a single-cavity mold, particularly when adjusting and aligning the various mold components.

- Limited Molded Part Size: Stack molds are most effective for small to medium-sized plastic parts. Larger parts may not fit within the confines of a stack mold, limiting their applicability.

- Increased Complexity: Stack moulds introduce a higher degree of complexity to the injection molding process, which can result in more opportunities for errors and defects if not managed properly.

- Cooling Challenges: Cooling is crucial in stack molds, and it can be challenging to maintain consistent cooling across all cavities. Poor cooling can lead to uneven part quality and potential warping.

- Injection Pressure and Timing: Stack molds require precise control of injection pressure and timing to ensure that all cavities are filled uniformly. Inconsistent pressure or timing can lead to part defects.

- Tooling Wear: The increased use and demands on a stack mould can lead to faster tooling wear and may require more frequent maintenance and repair.

- Limited Applications: Stack moulds are not suitable for all molding applications. They are best suited for high-volume production of smaller and simpler parts. Complex or large parts may not be efficiently produced with a stack mould.

- Ejection Challenges: Ejecting parts from a stack mold can be more challenging due to the vertical arrangement of cavities. Special ejection systems and strategies may be required.

Despite these disadvantages, stack molds remain a valuable tool for certain production scenarios where high efficiency and output are paramount. Manufacturers must carefully evaluate their specific needs and weigh the pros and cons of stack molds to determine whether they are a suitable solution for their injection molding operations.

Why We Need Stack Moulding

Stack molding is an essential process in the plastic manufacturing industry, as it allows for the creation of multi-colored or multi-material parts in one process. This method offers a cost-effective, time-saving, and efficient solution for creating plastic products that have unique design features, such as soft-touch grips or different textures on different surfaces.

Stack molding is also increasingly important in the production of consumer products, as it allows manufacturers to create products that are not only functional but also visually appealing, and this is a crucial aspect of attracting and retaining customers.

In conclusion, Stack molding is a valuable process in the plastic manufacturing industry, as it allows for the creation of multi-colored or multi-material parts in one process, resulting in cost-effective, time-saving and efficient solution for creating plastic products that have unique design features. It is increasingly important in the production of consumer products, as it allows manufacturers to create visually appealing products, which is crucial in attracting and retaining customers.

At Sincere Tech, we are dedicated to maintaining our position as a leading plastic mold company by embracing industry advancements and anticipating future trends. We actively explore innovative materials and composites that offer improved performance and sustainability. Through ongoing investments in research and development, we deliver cutting-edge solutions that address the evolving needs of our customers. As one of the best injection mold suppliers in China, we pride ourselves on our commitment to excellence.

In line with our commitment to sustainability, we prioritize environmentally friendly practices. We proactively seek sustainable alternatives, such as biodegradable polymers, and implement recycling initiatives to minimize the environmental impact of our manufacturing processes. By choosing our custom injection molding services, you can align your brand with sustainable manufacturing practices and contribute to a greener future.

Quality is of the utmost importance to us, and we maintain stringent quality control measures throughout the entire manufacturing process. Our state-of-the-art facilities and skilled technicians ensure that each product undergoes rigorous inspection and testing, guaranteeing exceptional performance, reliability, and customer satisfaction.

When you partner with Sincere Tech as your preferred China mold maker, you can expect the highest level of professionalism, expertise, and innovation. We are dedicated to helping you bring your ideas to life, delivering superior products that excel in performance, durability, and cost-effectiveness.

Our expanded capabilities include:

- Rapid Prototyping: We offer rapid prototyping services to quickly transform your concepts into tangible prototypes, allowing for iterative design improvements and accelerated product development.

- Precision Tooling: Our advanced tooling capabilities enable us to create high-quality molds with tight tolerances, ensuring consistency and precision in your injection-molded products.

- Overmolding: We specialize in overmolding, which allows for the combination of multiple materials or components, resulting in enhanced functionality, aesthetics, and durability.

- Insert Molding: Our expertise in insert molding enables us to securely encapsulate inserts within the molded parts, facilitating efficient assembly and enhancing product performance.

- Two-Shot Molding: With two-shot molding, we can produce complex, multi-material components in a single operation, reducing assembly requirements and enhancing design possibilities.

- Value-Added Services: In addition to injection molding, we offer a range of value-added services, including product assembly, packaging, and logistics support, streamlining your supply chain and reducing costs.

Partner with Sincere Tech Mould suppliers for your custom injection molding needs, and benefit from our comprehensive capabilities, unwavering commitment to quality and sustainability, and our drive to exceed your expectations at every step of the process. Together, let’s bring your innovative ideas to life.

Recent Comments