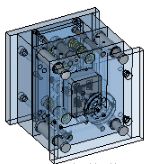

What is an injection mold?

An injection mold is a device made of metal to produce a plastic product faster, less expensive, and more consistent.

How does injection molding works?

Just heat the resin until it melts then force it into the cool mold. Allow it to solidify. Open the mold then take off the molded part.

That’s it!

As the molten resin is being injected into the plastic mold, it enters the mold opening called the sprue. From the sprue this molten material will then be distributed to the runners then it will be fored into the gate and then into the cavity. The cavity must be filled precisely to avoid short shots but it must not be over packed (over packing is forcing more than enough pressure to the resin and it can damage the mold). The molten resin will stay in the cavity for 30 seconds to 1 minute or more until it cools down and solidify. When the resin solidify a molded part is formed. The mold will open and then the molded part will be ejected. The mold closes and its ready for another shot.

Why is an injection mold expensive?

Injection molds are made up of special, high quality steels that have a good machinability property. Some  standard mold components such as springs, bolts, and limit switch are prefabricated and costs lower.

standard mold components such as springs, bolts, and limit switch are prefabricated and costs lower.

Most standard components such as ejector pins, ejector sleeves, sprue bushings, and leader components are not prefabricated which mean they will only be manufactured when you order them. They are not mass produced thus they are expensive. The cavity and core are mold components which make the mold really expensive. It involves careful design engineering and processing. Most of the tools used in making these components are very expensive.

Recent Comments