Plastic Molding Technology

In order to make various utilities around our homes, companies and other facilities that are of help to us we require various fittings which are plastic in nature. A good example is the water pipes we use at home and toilet fittings (elbows, cisterns, and bathtubs). All this are made with the help of plastic molding technology that makes good final outputs. This can be easily fitted to serve a range of purposes.

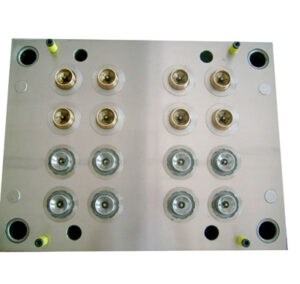

plastic mold and plastic molding manufacturing

A plastic mold refers to unfilled steel that can be different with different types of substances in order to come up with various products. Various materials can be discharged into the void between the steel to make various plastic molds, these substances can be of the following nature. Glass, ceramic, plastic and metal. In order to get a good casting after discharging the material into the void. After the have been discharged in to the vid they have to be left for some time for them to cool. This will cooled the steel is split to get the plastic molding or whichever substance that had been discharged in the void, the output required to be made depends heavily on the shape of the steel covering the void.

The molding mechanism was formulated

In the year 1872 by two male siblings, Isaiah and john. This is the apparatus that is very important in the plastic molding process. It uses the basics of the syringe whereby a machine discharges the substance that is intended to make the mold to form various appliances or tools of different shapes and sizes, without the help of this machine that was created by the two brothers, it would not be easy to make various plastic molds, other substances as it would involve a lot of activities that would be time-consuming.

The steps involves in making plastic injection mold

The widely accepted process of making a plastic injection mold is describes as follows,

plastic injection mold and plastic molding technology

with the help of UG software and AUTOCAD, development of a mold design is initiated and finalized, the stage that follows is the development of a suitable mold with the help of CNC and EDM technology. This is not complete without support of grinding and polishing actions. A mold has to be made appropriately under this step that follows; the fitting and assembly of the mold. This helps in the development of a mold that can be used to come up with the final output. These two steps are the most critical steps in the molding process. The next steps that follows is the preliminary stage whereby the ground plastic is introduced into the hot cavity to form a molten substance. This cooling process is then give chance in the injection mold. In order to get quality molds fast the shot has to be maintained at low temperatures, this is conducted with the help of oil or water flowing in cooling systems. Until then the mold is cooled and molding part is stabled in the mold cavity, then open the mold and ejector the plastic molding parts out, and then close the mold continue the whole process and start large production.

Plastic Molding Technology is continuously advancing and the future, it is going to be of advantages to mankind as it will provide various sizes of molds. This is from as low as 0.5 mm in size to 20 GM. There has also been mass production which in general will lead to a drop in plastic mold prices.

Recent Comments