Aluminum Caster Wheels: The Ultimate Guide to Smooth and Efficient Movement

In the world of industrial, commercial, and residential applications, mobility plays a crucial role in enhancing efficiency and productivity. Aluminum caster wheels, crafted from high-quality aluminum alloy, have emerged as the preferred choice for a wide range of applications, offering a unique blend of lightweight durability, corrosion resistance, and smooth operation. This comprehensive guide delves into the world of aluminum caster wheels, exploring their types, applications, selection criteria, installation process, and maintenance practices.

Types of Aluminum Caster Wheels:

Aluminum caster wheels come in various designs and configurations, each tailored to specific requirements.

Based on Design:

Single-Wheel Casters: Designed for simple applications, these casters provide basic mobility with a single wheel.

Twin-Wheel Casters: Featuring two wheels mounted side by side, twin-wheel casters offer increased stability and weight distribution, making them ideal for heavier loads.

Stem Casters: Perfect for applications requiring precise alignment, stem casters feature a stem that extends from the center of the wheel, ensuring accurate positioning.

Based on Swivel and Locking Options:

Fixed Casters: These casters provide straight-line movement, ideal for applications where maneuverability is not a primary concern.

Swivel Casters: Offering 360-degree rotation, swivel casters provide excellent maneuverability, making them suitable for applications requiring frequent direction changes.

Locking Swivel Casters: Combining the best of both worlds, locking swivel casters allow for both swiveling and locking, providing flexibility when both mobility and stability are essential.

Applications of Aluminum Caster Wheels:

The versatility of aluminum caster wheels extends across a wide range of industries and environments.

Industrial Applications:

Manufacturing Facilities: Aluminum caster wheels facilitate the movement of heavy machinery and equipment, enhancing production efficiency.

Warehouses: These wheels assist in transporting goods and materials smoothly, optimizing warehouse operations.

Laboratories: Aluminum caster wheels enable easy movement of equipment and tools, supporting scientific research and experimentation.

Commercial Applications:

Hospitals and Medical Facilities: Due to their ease of cleaning and disinfection, aluminum caster wheels are prevalent in healthcare settings.

Hotels and Restaurants: These wheels enhance the mobility of furniture and equipment, contributing to a more efficient and comfortable environment.

Retail Stores: Aluminum caster wheels allow for smooth movement of displays and merchandise, creating an engaging shopping experience.

Residential Applications:

Office Chairs: Ergonomic mobility is made possible with aluminum caster wheels, promoting comfort and productivity in office environments.

Furniture Casters: Adding mobility to furniture pieces, these casters facilitate easy rearrangement and space optimization.

Garden Carts: Gardening tasks become effortless with aluminum caster wheels, enabling the movement of heavy pots and equipment.

Selection and Installation of Aluminum Caster Wheels:

Choosing the right aluminum caster wheels is crucial for optimal performance and safety.

Selection Factors:

Load Capacity: Ensure the selected caster wheels can support the weight of the intended application.

Wheel Size: Consider the surface and environment to determine the appropriate wheel size.

Swivel and Locking Options: Select suitable swivel and locking mechanisms based on the desired mobility and stability requirements.

Installation Process:

Determine Mounting Method: Identify the appropriate mounting method for the application, such as bolt-on, weld-on, or press-in.

Align and Secure: Align the caster wheel with the mounting surface and secure it using the appropriate hardware, following the manufacturer’s instructions.

Maintenance and Care of Aluminum Caster Wheels:

Regular maintenance and care practices extend the lifespan and ensure the smooth operation of aluminum caster wheels.

Cleaning: Periodically clean the caster wheels to remove dirt and debris buildup, maintaining smooth operation.

Lubrication: Consult the manufacturer’s recommendations for appropriate lubrication intervals and procedures.

Inspection: Regularly inspect the caster wheels for signs of wear, damage, or loose fittings. Repair or replace them as necessary.

At Sincere Tech, we are dedicated to maintaining our position as a leading plastic mold company by embracing industry advancements and anticipating future trends. We actively explore innovative materials and composites that offer improved performance and sustainability. Through ongoing investments in research and development, we deliver cutting-edge solutions that address the evolving needs of our customers. As one of the best injection mold suppliers in China, we pride ourselves on our commitment to excellence.

In line with our commitment to sustainability, we prioritize environmentally friendly practices. We proactively seek sustainable alternatives, such as biodegradable polymers, and implement recycling initiatives to minimize the environmental impact of our manufacturing processes. By choosing our custom injection molding services, you can align your brand with sustainable manufacturing practices and contribute to a greener future.

Quality is of the utmost importance to us, and we maintain stringent quality control measures throughout the entire manufacturing process. Our state-of-the-art facilities and skilled technicians ensure that each product undergoes rigorous inspection and testing, guaranteeing exceptional performance, reliability, and customer satisfaction.

When you partner with Sincere Tech as your preferred China mold maker, you can expect the highest level of professionalism, expertise, and innovation. We are dedicated to helping you bring your ideas to life, delivering superior products that excel in performance, durability, and cost-effectiveness.

Our expanded capabilities include:

- Rapid Prototyping: We offer rapid prototyping services to quickly transform your concepts into tangible prototypes, allowing for iterative design improvements and accelerated product development.

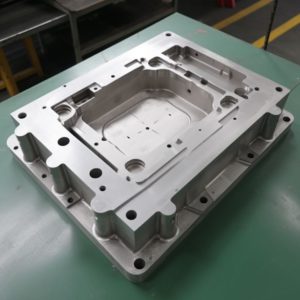

- Precision Tooling: Our advanced tooling capabilities enable us to create high-quality molds with tight tolerances, ensuring consistency and precision in your injection-molded products.

- Overmolding: We specialize in overmolding, which allows for the combination of multiple materials or components, resulting in enhanced functionality, aesthetics, and durability.

- Insert Molding: Our expertise in insert molding enables us to securely encapsulate inserts within the molded parts, facilitating efficient assembly and enhancing product performance.

- Two-Shot Molding: With two-shot molding, we can produce complex, multi-material components in a single operation, reducing assembly requirements and enhancing design possibilities.

- Value-Added Services: In addition to injection molding, we offer a range of value-added services, including product assembly, packaging, and logistics support, streamlining your supply chain and reducing costs.

Partner with Sincere Tech Mould suppliers for your custom injection molding needs, and benefit from our comprehensive capabilities, unwavering commitment to quality and sustainability, and our drive to exceed your expectations at every step of the process. Together, let’s bring your innovative ideas to life.

Conclusion:

Aluminum caster wheels stand as a testament to innovation and engineering excellence, offering a versatile solution for various applications. Their lightweight, durable, and corrosion-resistant nature makes them ideal for industries, businesses, and homes alike. By understanding the different types, applications, selection criteria, installation process, and maintenance practices associated with aluminum caster wheels, users can ensure optimal performance, safety, and longevity. Embrace the world of smooth and efficient movement with aluminum caster wheels, transforming your spaces into dynamic and productive environments.

Recent Comments